Fast & Accurate Data Collection

3D laser scanning uses LiDAR technology to accurately and efficiently capture three-dimensional data and reduces project delivery times by removing the need to shutdown infrastructure such as plants, rail and roadways. It also reduces associated labour costs and disruption to sites, intersections and restricted areas.

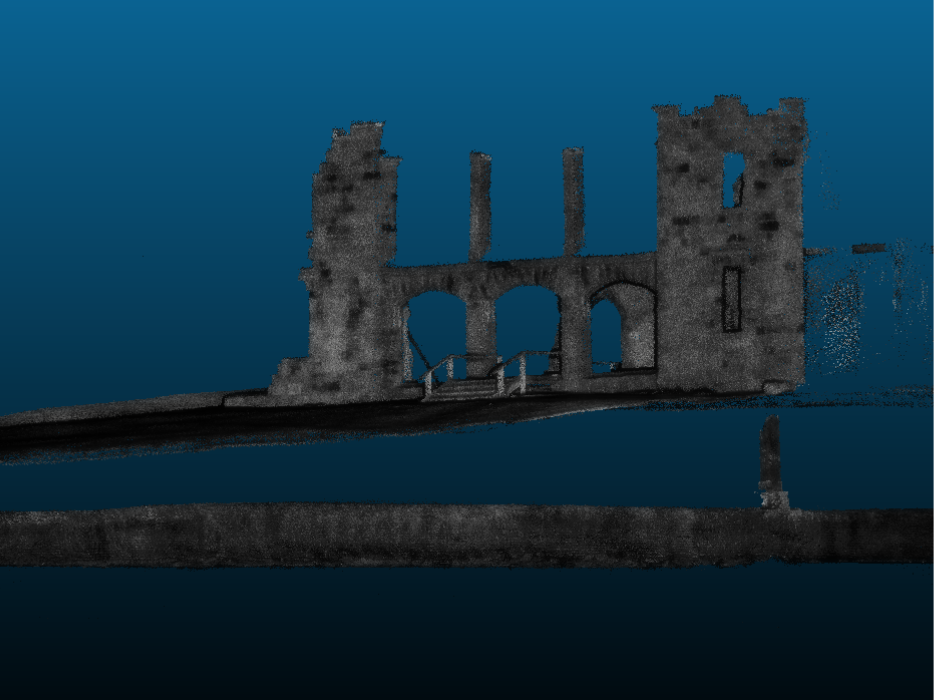

3D laser scanning creates clear and precise digital records without physically touching the structure being measured. Millions of measurement points, or ‘coordinates’ generate data that provides an exact measurement from and to any one point. It also produces high quality imagery via 3D visualisation techniques to market your project.

The scanning can be used to capture real world information, including construction verification, design engineering for upgrades and expansions, 2D and 3D building mapping, prefabrication, architectural documentation and collection of geospatial data.

Benefits of 3D laser scanning include gathering fast, rich details of every aspect of a project. It is also highly accurate. Individual measurements acquired manually are subject to errors, however laser scanning is the most accurate form of measurement available, delivering results within millimetres or less.

3D laser scanning reduces costs and captures extra data, eliminating the need to continually return to the project and minimises shutdown times and can obtain measurements in hazardous locations while keeping workers safe.

Benefits of 3D Laser Scanning

Faster Data Collection

- Project delivery times reduced

- Plant shutdown, rail occupations and road closure times reduced

- Labour costs to complete work reduced

- Disruption to sites / intersections / restricted areas reduced

One Homogenous Dataset

- Data can be viewed, navigated, measured and analysed quickly in 3D models

- Identification of design conflicts before fabrication or construction commences

- Datasets can be used in the future (data mined) for currently unknown requirements

- Ability to inspect complex environment from the comfort of your office thereby reducing costly site visits

- Fabricate or assemble offsite with reduced tolerances

- Reduce or eliminate expensive rework delays

- Higher level of detail aids design process

A Safer Way to Survey

- Remote acquisition and measurements increases efficiency and safety

- Eliminates the need to work at heights

- Removes the need to work in hazardous environments

- Gather information previously inaccessible using traditional techniques

Increased Accuracy and Detail

- Higher quality product deliverables

- Market your project using 3D Visualisation techniques